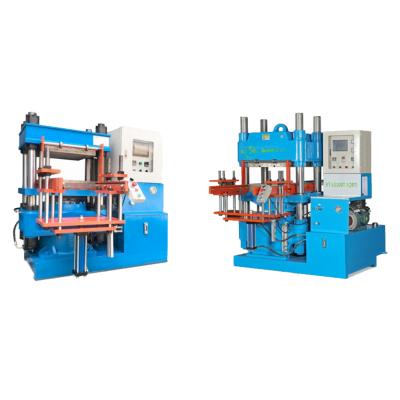

Motor automatic correction cylinderpressurized adhesive machine

Product Parameters:

|

MODEL |

KT-600C |

KT-900C |

|

Rated voltage frequency |

380V 50HZ |

380V 50HZ |

|

Heating power |

9KW |

12KW |

|

Pressurization method |

Cylinder pressurization |

|

|

Rubber roller diameter |

60mm |

|

|

Bonding temperature |

room temperature -200℃ |

|

|

Heating zone material |

Nickel-chromium wire mica sheet 3mm thickaluminum profile |

|

|

Heating zone size/mm |

1000*600 |

1000*900 |

|

Maximum use width/mm |

600 |

900 |

|

Conveyor belt adjustment method |

Motor fully automatic tensioning |

|

|

Speed control system |

Governor Speed Control Motor |

|

|

Internal structure |

Straight-line circular tape drive |

|

|

Installation size/mm |

L2140 W1150 H1110 |

L2140 W1450 H1110 |

|

Wooden box size/mm |

L1150 W1140 H1110 |

L1450 W1140 H1110 |

Applicable Industries

Shirt collar lining, seamless pressing andre-gluing, tape and elastic band shaping, gold and diamondburning,-melt composite of shoe upper and tongue, etc.

Configuration

1. lmported high-temperature resistant siliconerubber roller, 280'C, 6mm in diameter.

2. lmported temperaturecontroller (Autonics) and solid-state relay control.

3. Aluminummica sheet heating plate.

Features

1. The motor cooperates withthe company's patented bias correction mechanism toautomatically adjust the tape, preventing it from running off ordamaging the high-temperature tape.

2. The cylinder cooperateswith the lever pressurization mechanism, providing a pressure ofover 5kg, which is more suitable for high-strength bonding.

3. Anti-static high-temperature seamless tape, sturdy and durable.

4. Dual temperature control and dual solid-state control,suitable for different fabric composites.

5. solid high-temperature silicone rubber roller does not deform under highpressure, ensuring that every point of the fabric can receiveuniform pressure.

6. Built-in corrug roller prevents wrinkles andfolds in thin materials.