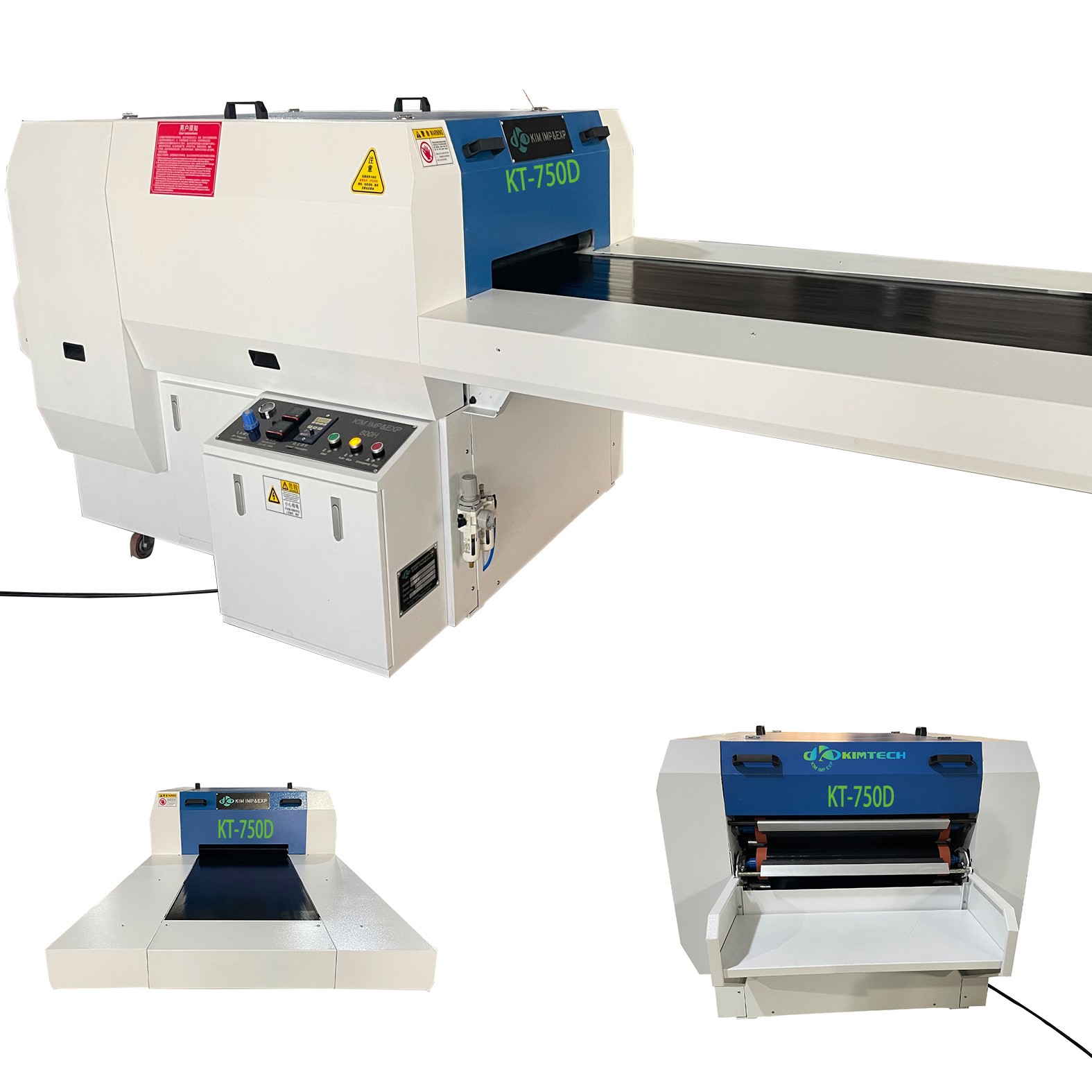

Multi-Function Laminator KT-750D

Thermal system:

Using high-efficiency and energy-saving mica plate heating board, the temperature is more balanced in the left middle and right.

Heating area configuration:

1、Temperature up and down separately

2、High heat conduction efficiency, heat loss is small

3、Accurate temperature control, small temperature change

4、Heating board non-heat conductive surface insulation design to achieve the minimum of thermal dispersion.

Pressure system:

Pressurization system is second only to heating system, affecting the second most important factor of adhesion quality. This machine adopts the double roller double pressure system of large silica gel bar.Heat and cold pressure. Incoming system:

1、The machine uses the feed conveyor belt and the heating zone conveyor belt as a whole belt,there is no section in the middle, so as to facilitate the smooth transmission of small materials Steady into the temperature zone.

2.The feed table is large, can place large size fabric, suitable for many people to operate, maximize the machine usage rate.

Refrigeration system:

1、The machine adopts water-cooled cooling, a total of seven cooling panels under four.

2、Standard with 3 ice dispensers, you can also choose 5 ice dispensers.

3、Machines and ice dispensers use split body design. Do not worry about the temperature in the small room.

Product Parameters:

1.Model:KT-750D

2.Width:750mm

3.Temperature range:30-200℃

4.Working pressure:0-0.4mpa

5.Velocity band:0.1-10m/min

6.Control Mode:Motor adjustment belt

7.Power voltage:380V,

8.Total power:21.6kw

9.Cooling power:3kw

10.Size:5200X1380X1330