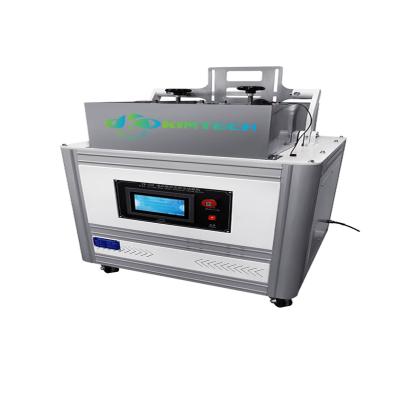

Single Group Vulcanizing Machine 50tons KT-DJ50T-1

Application scope:

The vulcanizing is suitable for the vulcanization of various silicone rubber products and is an advanced hot pressing equipment for the compression molding of various the rmosetting plastics. The vulcanizing machine is divided into three types: electric heating, steam heating and oil heating. This machine has complete functions and compact structure. It has timed mold locking, automatic pressure compensation, automatic temperature control, and automatic timing. The surface temperature of the hot plate is uniform, the temperature control is accurate and intuitive, and the pressure maintenance is stable and reliable. With the characteristics of safe and convenient operation, the use of this machine can ensure product quality, improve production efficiency, and obtain significant economic benefits.

Product Parameters:

1.Model: KT-DJ50T-1

2. Hot plate specifications: 350*350mm

3. Temperature range: normal temperature -350℃

4.Hot plate spacing: 150mm

5. Heating method: imported electric heating tube

6. Mold opening method: automatic mold release

7. System pressure: 18MPa

8. Main column diameter: Φ180mm

9. Clamping stroke: 160mm

10. Working level: upper and lower levels

11. Motor power: 3.75KW

12. Maximum pressure: 50 tons

13.Total power: 11KW

14. Machine structure: four-column/single-head model

15. Power supply specification: 380V/50HZ

16. Overall machine size: 1400*1200*1500mm

17. Machine weight: 1000Kg