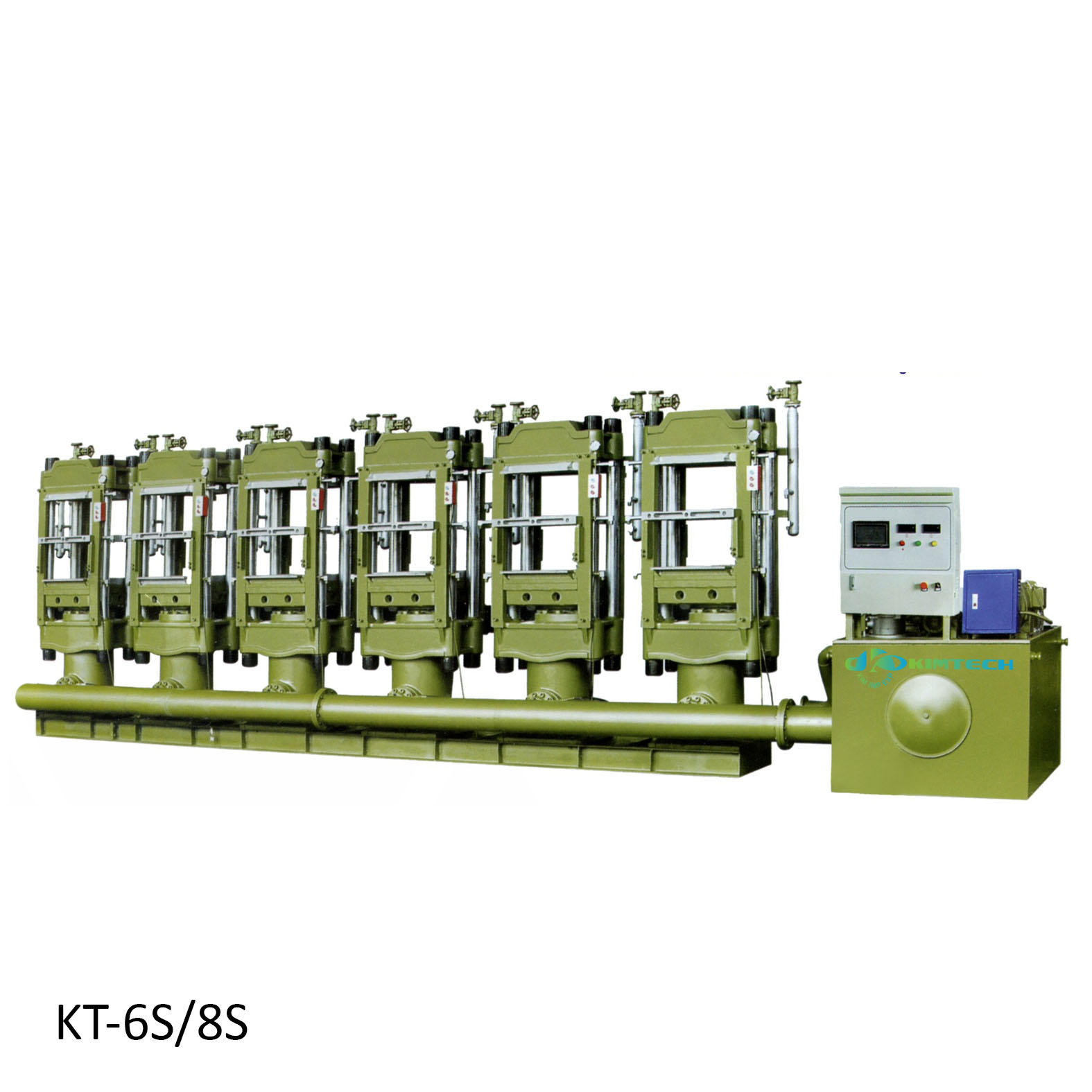

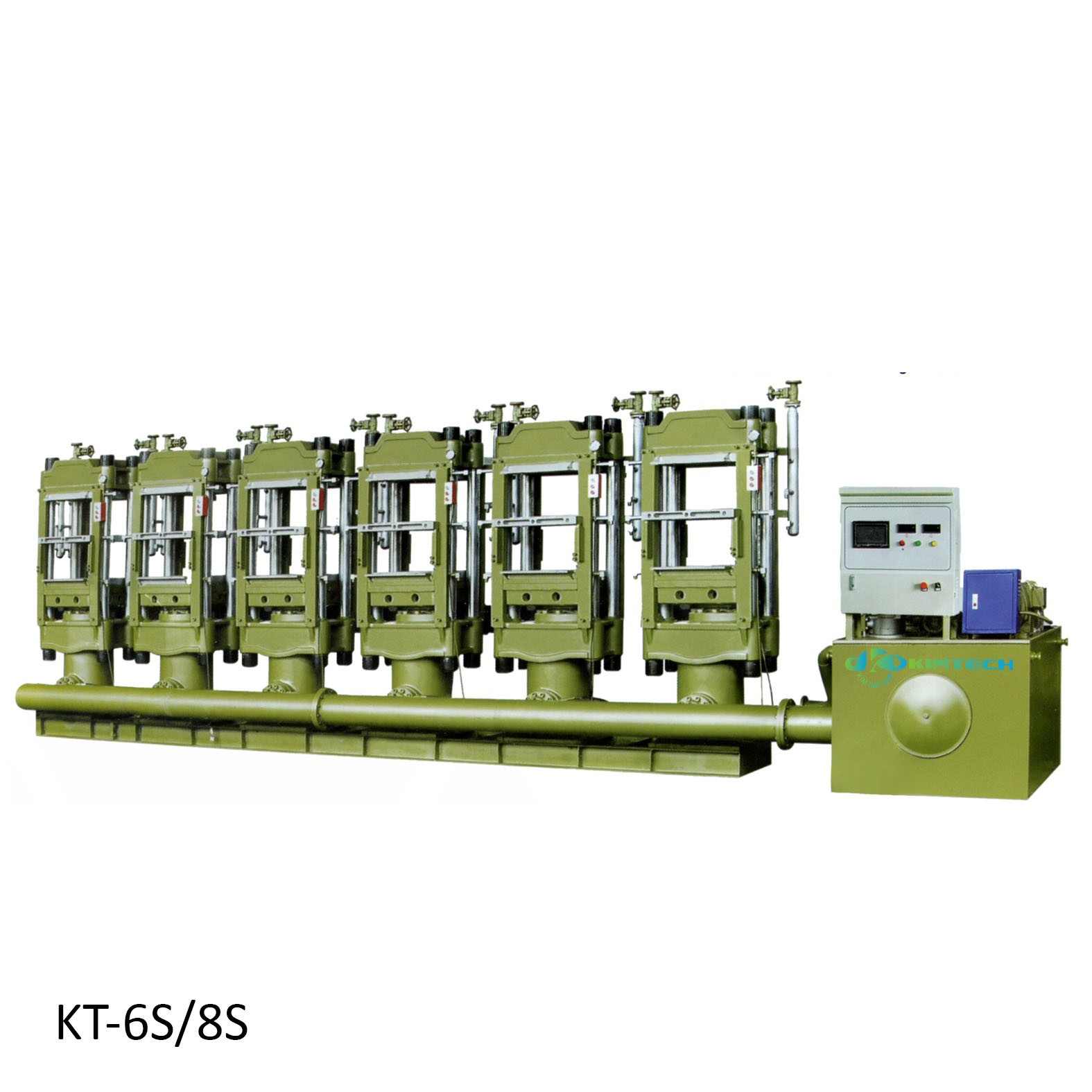

EVA Small Foam Molding Machine

Product Parameters:

1. MODEL :KT-6S/8S

2. Number of work stations :6/ 8/10

3. Mould clamping force(Tons) :150/200t

4. Vould size(mm) :550 x 550 mm

5. Mould size(mm) :600 x 600 mm

6. Layer number of each station :2

7. Daylight between plate(mm) :240 x 300 mm

8. Heating way :Oil Heating / Steaming / Electricity

9. Motor power(kw) :15 kw

10. Weight(Tons) :17/27t

11. Machine dimension(m) :10x1.3x2.7m

Features:

High Efficiency:

Adopted specific steel pipe to make heating plate, increase thermal conductive area, rapidly heating and foaming, the efficiency is 20% higher than the same kinds of products

Energy saving:

The machine uses thermal keeping design and a thermal isolation cover is formed around the machine set,thus 20% of energy can be saved

Time Saving:

The machine be equipped with PF150 prefil valve,can rapidly drops in the shortest time. lt save much more time and can produce more pairin one day.

Control system:

Adopt PC and PLC control system than imported from abroad famous brands, works through a graphic display interface to show all monitoringinformation and setting conditions.

Hydraulic system (Oil pressure system):

By adopting proportional controlling valve,also with the support of computer control system,can accurately keep control of the fow of oilpressure,are used to keep down noise but increase efficiency.