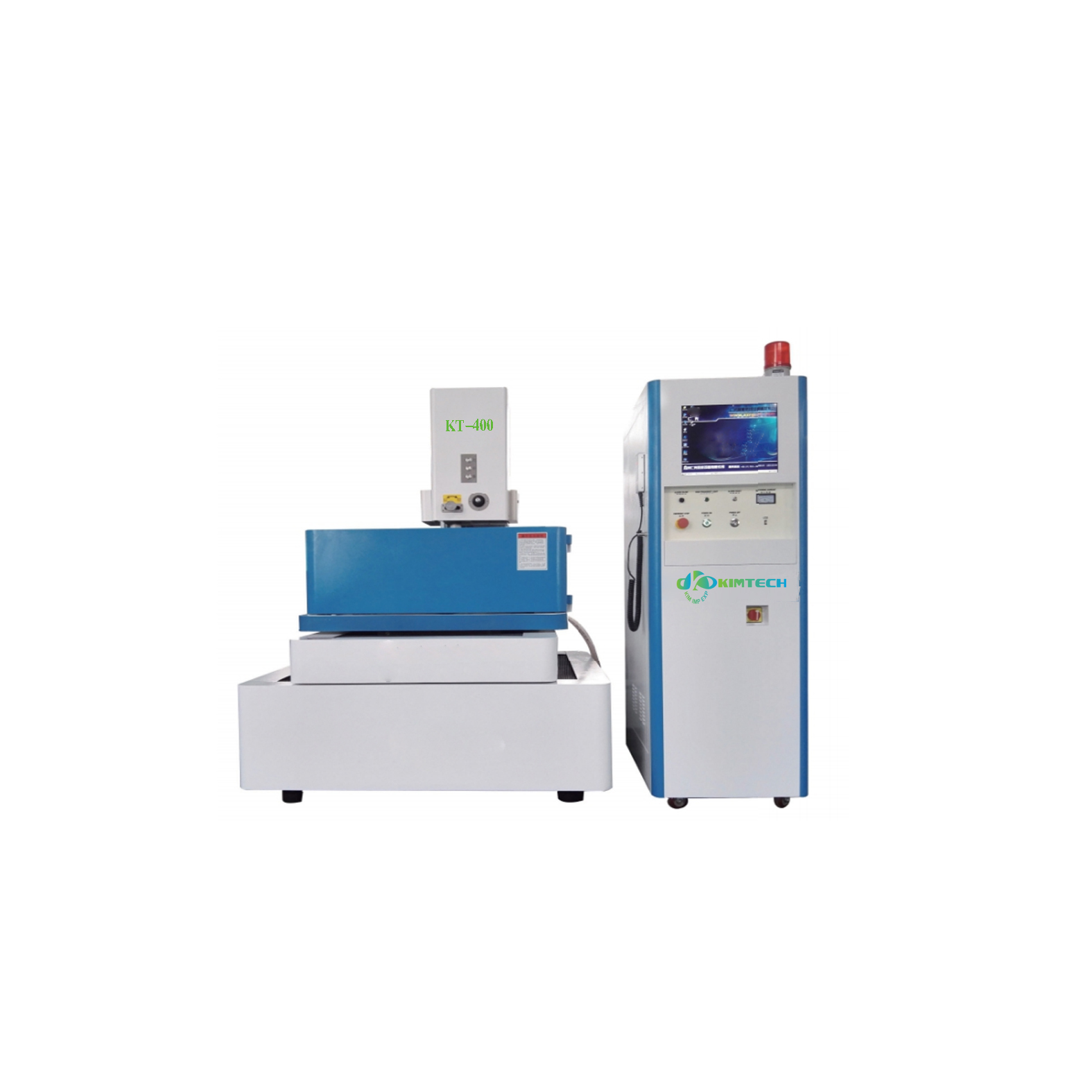

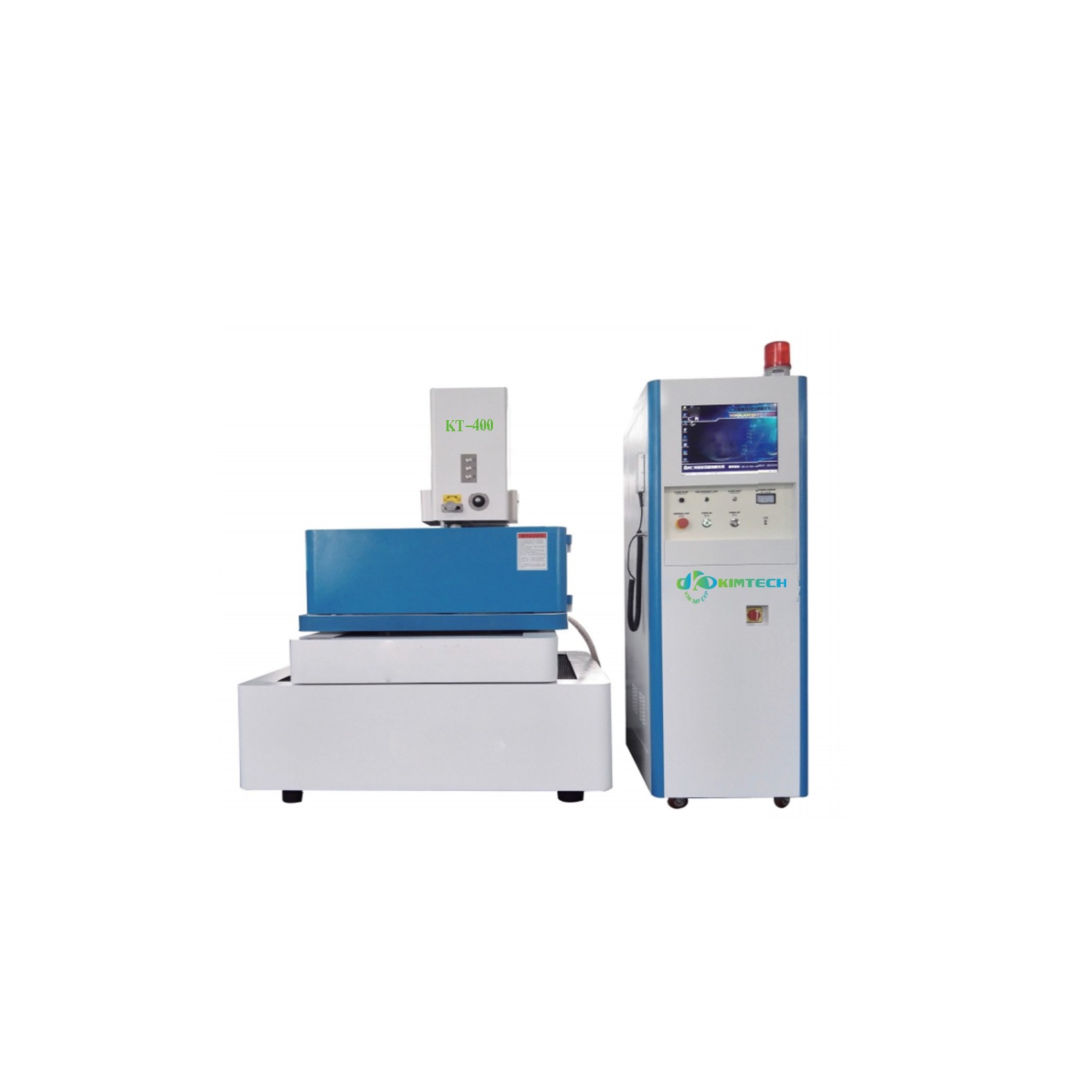

Deluxe Servo Medium-speed WEDM Machine KT-400

Features:

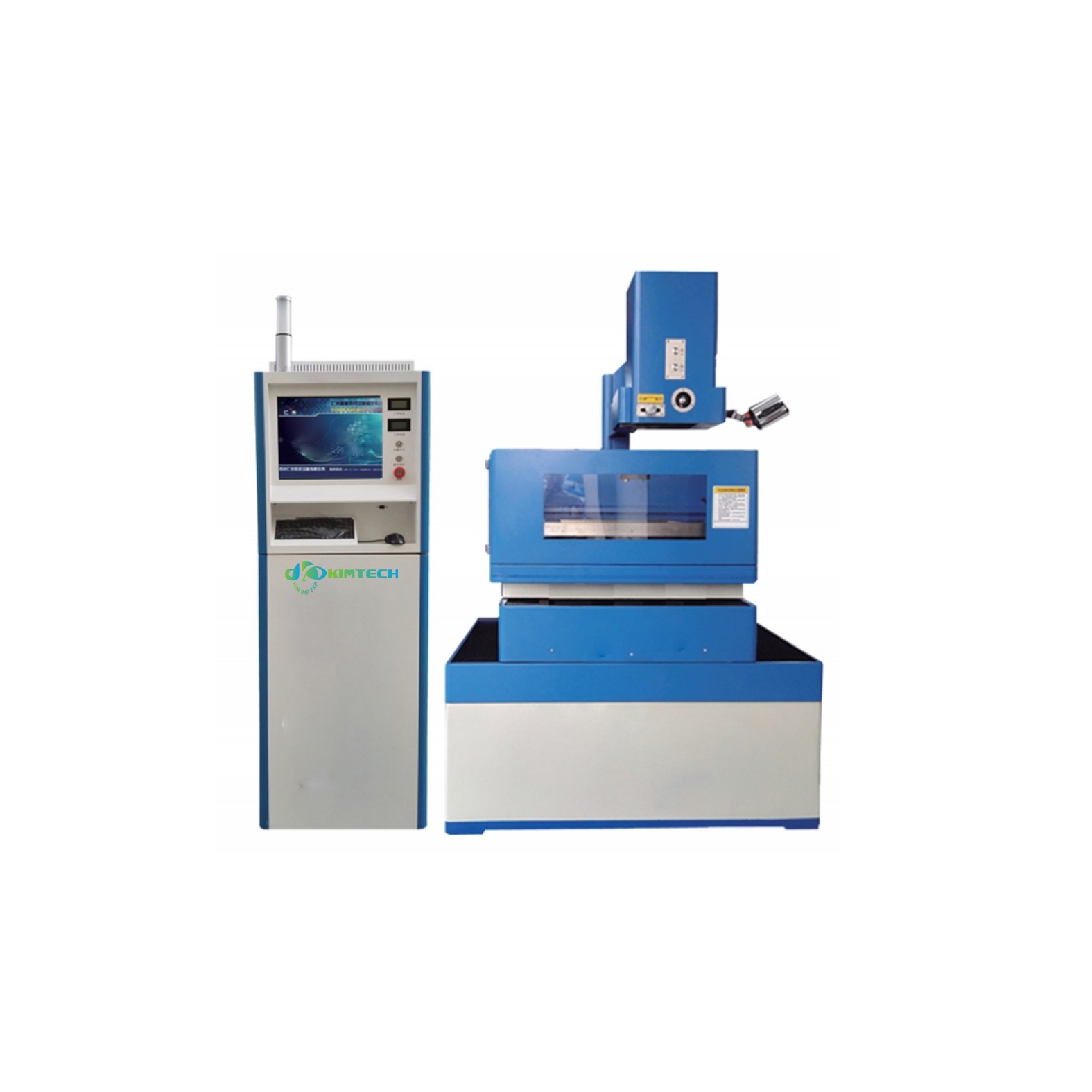

Mechanical part:

1.The machine bed was made from iron with resin sand casting technology.

2.The machine tool adopts the full support T-type bed structure and the C-type Z axis structural column which can bear high loads.

3.The table X/Y axis adopts double-nut ball screw from Taiwan Hi win,the guide rail adopts high-grade linear guide rails from Taiwan Hi win;and the U/V and the wire drum also adopt linear guide rails from Taiwan Hi win.

4.The constant wire tension mechanism of upper-and-lower double wire tightening device is adopted.

5.The exclusive waterproof black stone guide wheel is a standard feature;patented wire leading faucet is used.

6.The low-speed composite work piece holder is a standard feature.

1.High frequency: adopts integrated circuits to subdivide the pulse power supply, and realize high-speed machining with up to 160 mm2 per minute, an optimum surface roughness of Ra1.0um and the electrode wire loss of 0.01mm for every 100,000 mm2 of machining.

2.XY driver: adopts AC servo motors and actuators from Japan Yaskawa for the XY axes which are more quick, more stable and more precise.

3.Host: installs Win xp and Win 7 systems as well as Auto Cut RG programming and controlling software, together with man-machine dialogue in Chinese and English which makes machining simpler and more stable.

4.Communication interface: RS232, NIC, USB.

5.Control mode and number of spindles: four spindles linkage.

6.ISO code:ISO code,compatible with 3B language, and graphic texts in DXF format of AUTOCAD/CAM.

7.Precision of single pulse feed: 0.001 mm.

8.Programming and controlling system: Auto Cut RG.

9.Interface language:Chinese/English and other 5 languages.